Fluororubber(FKM) is simply a synthetic elastomer with fluorine atoms attached to the carbon atoms in its main chain or side chains. It features high temperature resistance, stable chemical properties, resistance to wind, sun and oxidation, as well as oil resistance and extremely low air permeability.

In the military industry, it is indispensable in fields like aerospace and aviation. It is widely used in seals, oil pipes and electrical wire sheaths for launch vehicles, satellites, fighter jets and new-type tanks, making it an irreplaceable key material in cutting-edge national defense industries.

①FKM History

The history of fluoroelastomers (FKM) starts with research into fluoropolymers back in the mid-20th century. The main goal was to overcome the limitations of plastics when used as sealing materials. Early attempts, like the prototype developed by DuPont in 1948, didn’t really work out industrially. It wasn’t until the late 1950s that a breakthrough came. The first commercially viable fluoroelastomer was a binary nitroso type, which emerged in the United States. It had good low-temperature flexibility and strong oxidation resistance. DuPont stepped up in 1957 with an aerospace-grade FKM. Then in 1959, they introduced a ternary copolymer (VDF, HFP, TFE), which had better thermal stability and solvent resistance. China began its own research in 1958. Early developments included types like FKM23 and FKM26. Later on, they moved on to products like tetrafluoroethylene (F1PM) and perfluoroelastomers (FFKM).

②FKM characteristics

The molecular structure of FKM determines its excellent chemical stability and high temperature resistance. The f atom surrounds the carbon chain and carbon bond, making the carbon atom vulnerable to attack by other chemicals, molecules, atoms or atoms. The structure of tetrachloride ion is shown in the figure below:

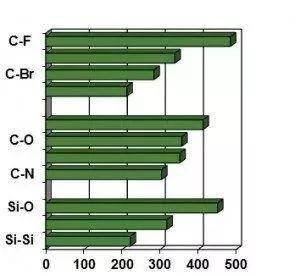

In addition, the bond energy of the fluorocarbon bond is very high, which also means that it is not easy to break and its chemical properties are very stable.

③Application areas of FKM.

According to statistics, the global FKM production capacity is approximately 90,000 tons, with an annual consumption of about 50,000 tons. Internationally, major FKM manufacturers include 3M and Solvay, among others. In China, large-scale production of FKM is already in place. Manufacturers of high-performance FKM include “Jiangsu MIS Rubber: and Chenguang Chemours, etc. Data source: ACMA. In 2022, China’s FKM production capacity was about 28,000 tons per year, and it is expected that the annual growth rate of FKM will remain around 8%.Application areas of FKM.

FKM has become an indispensable material in industry, playing a significant role in fields such as military industry, aerospace, automotive, and petroleum. It is widely used in the production of sealing products. Currently, over 60% of FKM worldwide is applied in the automotive industry. For example, the hydraulic systems of loading and unloading trucks and large unloading trucks work for a long time, causing the oil temperature and component temperature to rise rapidly. Ordinary rubber cannot meet the working requirements, but FKM products can meet various harsh technical requirements with their excellent temperature resistance. Moreover, as the automotive industry’s requirements for reliability and safety continue to increase, the demand for FKM in the automotive sector is also growing rapidly. Beyond the automotive industry, FKM is also used in machinery, oil refining equipment, natural gas, and power plants, among other fields. It is commonly used as packing, diaphragms, and gaskets for engines, pumps, reactors, mixers, and compressor housings. Additionally, FKM is an indispensable part of the material fields for modern aviation missiles, rockets, space navigation, atomic energy ships, and so on.